Q. No. 7 Explanation of Supply Chain Decision Phases with Examples Based on Timeframe.

Supply Chain Decision:

Decision Phases in Supply Chains: Explanation and Examples

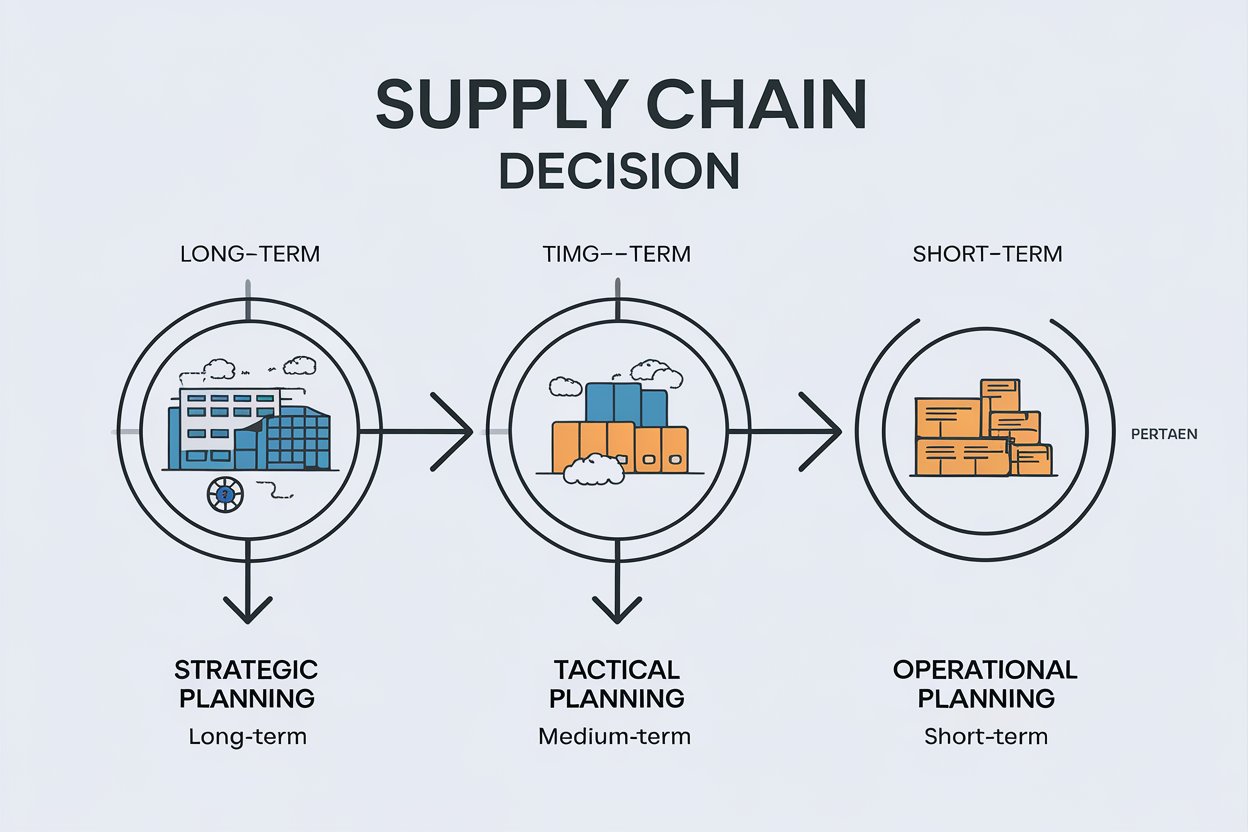

Supply chain management involves making various decisions that are categorized into three major phases, each corresponding to different timeframes and levels of impact on the supply chain. These phases are Supply Chain Strategy/Design, Supply Chain Planning, and Supply Chain Operation.

1. Supply Chain Strategy/Design Phase

This phase involves high-level decisions that shape the long-term structure and capabilities of the supply chain. These decisions typically have an impact over several years and cover aspects such as the number of facilities, warehouse locations, product flow, and technology adoption.

Example:

- A global automotive company deciding on the location of its manufacturing plants in different regions based on cost, logistics, and customer demand projections.

Advantages:

- Provides a framework for long-term sustainability.

- Allows alignment with corporate strategy and market trends.

Disadvantages:

- Costly and difficult to reverse once the decisions are implemented.

- Relies heavily on forecasts, which may be inaccurate over long time horizons.

2. Supply Chain Planning Phase

The planning phase covers decisions typically made on a medium-term basis, such as quarterly or yearly. It focuses on efficiently using existing supply chain resources and balancing demand and supply. These decisions include inventory management, production schedules, and workforce planning.

Example:

- A retail company planning its seasonal inventory levels based on expected consumer demand during holiday periods.

Advantages:

- Flexibility to adjust operations based on changing market conditions.

- Helps in optimizing resource utilization and cost reduction.

Disadvantages:

- Planning is reliant on accurate demand forecasts; errors can lead to understocking or overstocking.

- May be constrained by existing supply chain design and infrastructure.

3. Supply Chain Operation Phase

This phase involves day-to-day decisions focused on short-term execution, such as managing orders, deliveries, and transportation. These decisions are highly detailed and deal with real-time constraints and customer needs.

Example:

- A logistics company coordinating daily shipment schedules to ensure timely delivery to various retailers.

Advantages:

- Ensures smooth and responsive operations in the short term.

- Allows for rapid adjustments to unexpected events, such as delays or disruptions.

Disadvantages:

- Often reactive, dealing with problems as they arise rather than preventing them.

- Limited ability to influence long-term outcomes as it operates within the constraints of earlier strategic decisions.

Conclusion

Each decision phase in supply chain management serves a distinct purpose, ranging from long-term strategic planning to short-term operational execution. While the strategy/design phase lays the foundation for long-term success, the planning and operation phases ensure efficient use of resources and timely responses to daily challenges.